2 min read

Tackling Combined Sewer Overflow Issues in Middletown, Ohio

![]() Jacqueline L. Mulhern

:

Jul 28, 2022 3:04:25 AM

Jacqueline L. Mulhern

:

Jul 28, 2022 3:04:25 AM

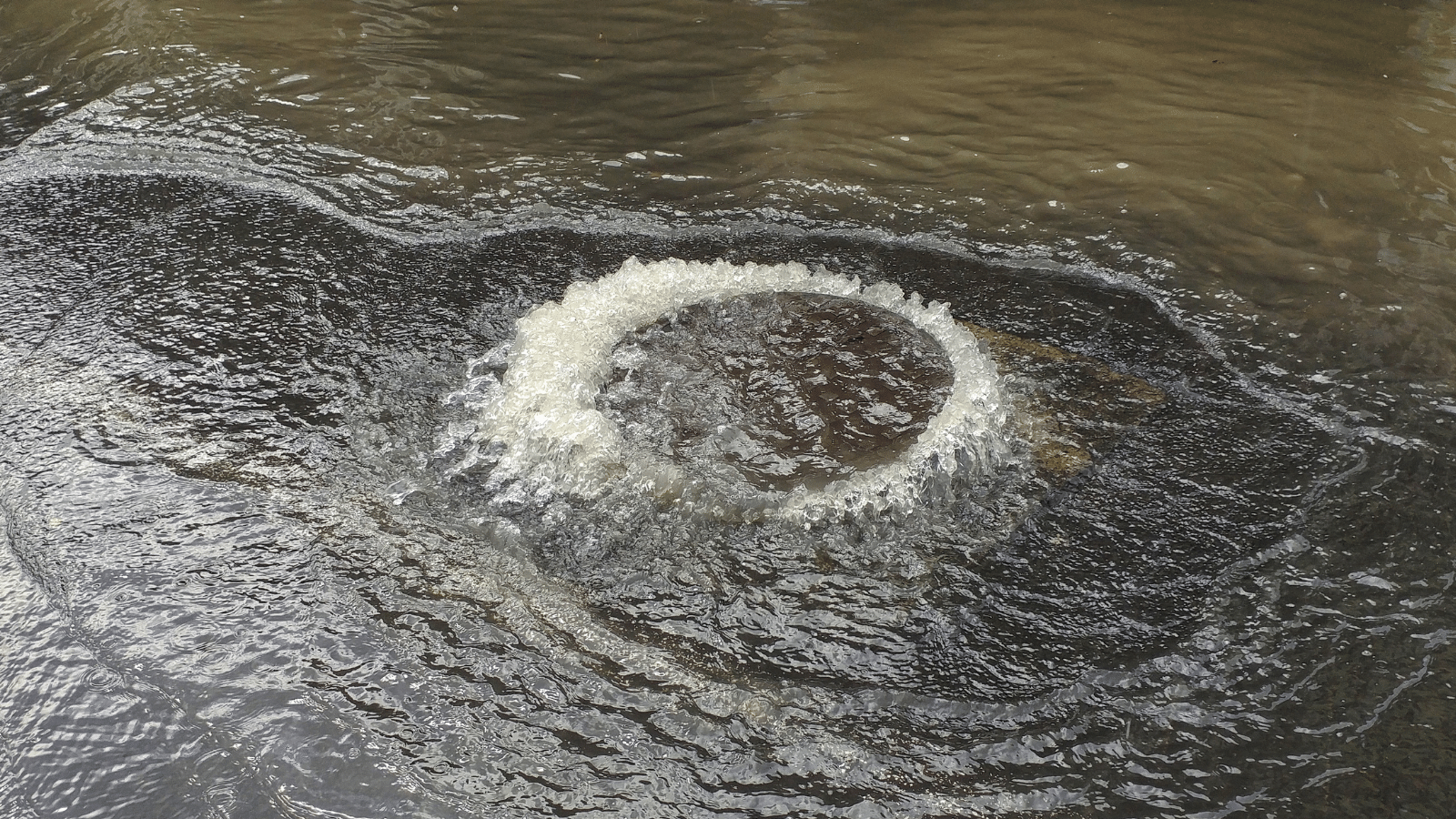

Middletown, Ohio, is home to almost 50,000 residents and over 300 miles of sewer pipes. Established in the 1800s, this historic town uses a Combined Sewer Overflow system to drain both sewage and rainwater. This aging system of pipes was frequently overwhelmed when confronted with heavy rainfall causing untreated sewage to spill onto the streets, draining into the Great Miami River, and then flowing onto the Ohio River.

Combined sewer overflows severely polluted the water and resulted in the US Environmental Protection Agency issuing a consent decree. Changes had to be implemented to eliminate, or at least severely reduce, overflows by 2034.

As part of the process of cleaning up this wastewater spillage, the utility enlisted a new plant manager in 2011. This manager prioritized transferring as much as possible from manual to digital processes. Mountains of paper gradually became small hills as the water utility moved its work online. But some activities were disconnected from the digitization progress.

First Try at a Solution

“I am a wastewater systems supervisor, but I felt like a firefighter. Every morning I arrived to work ready to put out fires, the urgent and important problems needing repair. I never knew what problem was waiting for me. But something was wrong every morning.”

Throughout Middletown’s sewer system, bulky cabinets housed Programmable Logic Controllers, or PLCs, connected to sensors that measured overflow. Data from the PLCs were transmitted over a radio network, requiring a direct line of sight between the PLC and receiving transmitter in the plant. Anytime a storm moved the antenna a few inches or nearby construction shifted the heavy equipment, the transmission was lost until a field team repaired the complicated setup.

The old PLCs frequently broke down. An IT professional only repaired the system when multiple PLCs needed fixing. While the PLCs were down, Middletown wastewater employees stood in the rain to manually track overflows using chalk markings to measure the level.

The Ayyeka Solution

Middletown needed a reliable technology to consistently track and gather overflow data. “With only 5 guys, my small crew couldn’t handle another big task,” said Barker, Supervisor at Middletown’s Water Reclamation Facility.

The Ayyeka solution was deployed to track level changes and monitor overflows. The Ayyeka Wavelet edge devices operate fully autonomously on battery and are deployed throughout Middletown’s sewage collection network. Every 10 minutes, the Wavelet measures sewage levels. Every hour, those measurements are securely transmitted to Ayyeka’s Field Assets Intelligence (FAI) software platform.

If the Wavelet detects a slightly abnormal level measurement, it transmits the data to the FAI software every 30 minutes. If an overflow event occurs – as defined by a severe level change – Barker and his team receive an immediate text, email, or automated phone call notification, and the data is transmitted every 10 minutes.

With the Wavelets monitoring levels throughout Middletown, Lance and his team know where and when overflows occur. With a click of a button, the detailed data is exported from Ayyeka’s FAI software for simple compliance reporting.

“Ayyeka works really well for us because it’s simple,” said Barker. “It doesn’t take a lot of time or effort to install – it’s truly a plug-and-play solution.”

Now that Barker’s team spends less time manually measuring overflow events in the field, there is time for preventative maintenance.

"My team makes fewer trips to the field because the Wavelet devices are much more durable than the old PLCs,” said Barker. “And, if anything goes stops working, instead of waiting for an IT guy to come to fix it, my guys can easily switch the Wavelet device.”

He added that “Now we aren’t busy putting out fires and fixing something every day. When there’s time for proper maintenance, there are fewer problems overall.”